Some toilets are better equipped! #prusa SL1S resin printer @ https://jkl.hacklab.fi/

#prusa

And Prusa continues, so disrespectful 🤮. Flagged so many times for their wrongdoing, yet they persist in trying to redefine open source for marketing purposes. Champions of open-source-washing!

➡️ The OCL isn't an open source license

I wish I could stop writing those posts but apparently most of the media continue to copy their words without doing a quick search.

Btw, their CAD files are just like STEP files, no logic, certainly not a source.

Dave Randolph, creator of PrintedSolid has resigned from its CEO position and departed. Prusa is now taking the lead.

Dave, if you read here, thank you very much for all the great and hard work. Thank you for having trusted my project and sold many Bear frame kits. I wish you all the best for the next steps 💫

More info: https://techhub.social/@fabbaloo/116046895268921557

#printedsolid #jessie #filament #3dprinting #prusa #bear #bearupgrade @printedsolid

After 12 hrs 3D printing and 3 more to go, our electricians decided to cut power to some sockets in my office.

I do think the printer even moved the head to the back as an emergency move before it lost power completely.

After finding some extension cord and rebooting the system, I only get a "Warning, bed cooled down, objects might not be attached anymore" before I could resume the print.

It's the first time that happened to me, but one of the reasons I love my #Prusa :-).

I was just changing the nozzle on one of my #prusa mini 3d printers, and I noticed that it has over 11.000 printing hours. Apart from the regular replacement of tubes, I've not had any difficulties with it. That's pretty good guys!

https://www.prusa3d.com/product/original-prusa-mini-3/

#3dprinting

This is amazing!

Someone made a 3d print model for turning an empty Prusament spool into a robot: https://www.printables.com/model/1583116-prusa-spool-bot/comments

#Prusa #3dPrinting

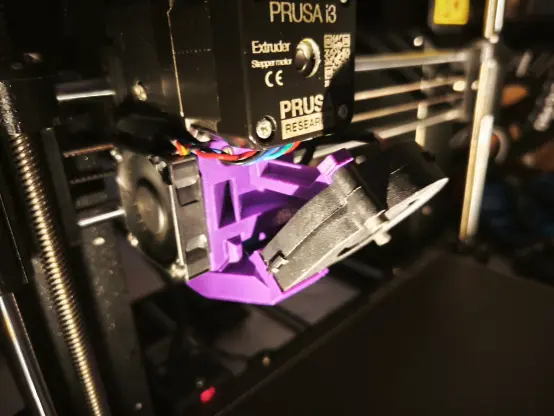

one of the best things having a 3D printer:

You can simply print stuff, when printy needs some service and replacement parts.

and these parts were my 1st steps into printing ASA filament :cute:

#3dPrinting #3dDruck #Prusa

@FreeCAD I have uploaded my filament storage/dry box project. 🙌

You can find it here:

https://www.printables.com/model/1587660-filament-dry-box-from-food-storage-container

Additionally, here is the customized side handle for Prusa CORE One that is also visible on the photo.

https://www.printables.com/model/1587685-side-handle-for-pc4-m6-pneumatic-coupler-for-prusa

#FreeCAD #FreeCADFriday #3DPrinting #3DPrint #DIY #Prusa #PrusaCoreOne

"Organic" is done and mounted! When I installed the heat pump head I left room. This fills that space as planned, completing my shop office. It works, could tell the time accurately, and sounds great. I've done two passes at setting the beat, but the Home Assistant display below shows the time anyway. This wall combines the old and the new.

The left weight is a small bottle with ferrite core memory. I picked it up at a computer show in the mid 1970s. The weight on the right is a miniature Luthier’s plane. The motor weight is a Lee Valley “Flat Bob” and a Lee Valley carabiner watch. The red end caps and finial are my own design in #FreeCad printed on a #Prusa CORE One. The clock gears are Baltic Birch plywood. The other parts are figured Maple, with a thin plywood backing.

This is my third Clayton Boyer design. I haven't decided on the next.

Meanwhile, the production never stops. "A storm is coming..."

#3Dprinting #PrusaMini #Prusa #Makerspace

My #Prusa MK3S (started as a MK3, upgraded along the way) starting making weird squeaking noises, coming from one side of the bed. Shone a light under there during printing, and the bearings on the left side are slipping around quite a bit in the U-bolts that are supposed to be holding them to the Y-axis carriage.

I'm surprised this isn't interfering with the printing, but it still needs resolving. Looks like the Sunday project will be a partial teardown of the printer.

A moment of zen. Two 3D printers in perfect synchronization. 🧘

Finally, a post about the #Prusa #CoreOne that isn’t a complaint about incompetent factory assembly: did you know the advanced filtration system pretty much won’t run for PLA/PETG unless you lie to the printer about the material type?

I’m not entirely sure what the “DIY filtration” option in firmware does because why would you need to document your software? And I have no reason to think it’s not also filament type dependent.

I understand PLA is not necessarily harmful but it has gotten stinkier over the years and I don’t like it.

There is in fact no calibration procedure for the side filament sensor. You can’t fail QA at the factory if you just don’t Q the A!

It might just be an issue with a magnet not being pushed in far enough, but regardless it’s going to require complete removal of the side panel. Love to get all these basic-ass printer assembly 101 mistakes.

I almost don’t want to bother because the INDX setup obviously doesn’t use this sensor at all, but that would leave me with no way of doing filament runout properly.

I did fix the z-axis binding, I think. I printed the alignment tools but I think it was really just the screws being too tight. Tighten the screws, but not Too Tight!

Hier im #Fediverse sind ja einige Enthusiast*innen für 3D Druck unterwegs (z.B mit #Prusa etc.)

#CarlRoth bietet jetzt auch #BioPrinting an.

D.h wenn eure Organe kaputt sind, könnt ihr sie einfach nachdrucken lassen. Wie geil ist das denn? 🤓😃

And finally, I'll trade you something nice for the #3dprinting crowd at #FOSDEM. #Prusa didn't get a booth because life happened to Pavel (not on Mastodon), but there will be a Core One with high temp nozzle at the #Grafana booth. I did ask for PEKK-CF and they should be able to bring a spool. That would be fun. I touched it a few times but never printed with it.

Edit: changed PEEK to PEKK-CF, thanks @fribbledom