I just put in an order for some replacement parts I messed up on my RV-10 elevator as well as the sealant kit they recommend. So I think I'm getting ye olde motivation to go finish those elevators.

#Homebuilt

Here is a very short video clip of me installing a pull rivet from the inside view. The Zenith CH750 gets a tiny bit closer to done.

#rivet #riveting #experimentalAviation #homebuilt #kitplane #avgeek

The glider now has 12 pounds of lead shot and epoxy added to dead space in the very end of the tail boom.

My initial estimate of volume indicated that I could add 8 - 10 pounds this way. I'm pleasantly surprised, and I didn't make a chocolate covered mess of things as I was pouring this goop into the tail.

I need to add a few more pounds to the tail. Phase two of this project will use lead plate, bolted to the vertical fin spar. (I need to unroll the 1/4-inch plate first, then develop a template to cut the lead.)

I could not add the epoxy/lead shot mix all at once because of the exothermic reaction of epoxy. When mixed epoxy is in a thick blob (instead of a thin layer), it generates enough heat to warm itself...which accelerates the chemical reaction...releasing more heat...further accelerating the reaction.... I have seen epoxy smoking hot because of this, so I added a bit, waited a half hour, checked temperature with an IR non-contact thermometer, added a bit more when it was clear that the exotherm was only very mild, etc. That took a while, but turned out well.

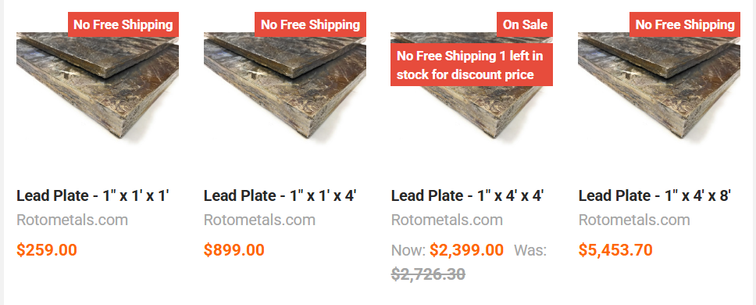

I note that Roto Metals has a discount on some 1-inch lead plate. Get your fork lift ready. No free shipping!

https://www.rotometals.com/lead-sheet-plates/sheet-lead-1-64-lbs-sq-ft/

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Ballast #Math #Density #Exothermic #Chemistry #Thermodynamics #Lead #Epoxy

The workshop was pretty neat. Aside from learning a bunch of the theory and getting recommendations for books and whatnot, you do some hands on stuff which is always a great way to learn. On day one we did various crimping practice and made a wire harness connected to aviation headset jacks and once we were done, we plugged it into an actual intercom to test it (and it worked, which feels great).

Second day we went over antenna theory and some things there, then made a coax cable end (tedious to be sure). The final project was soldering and crimping to simulate building a part of a panel. Basically a lighting circuit for nav lights and the panel lighting is tied to it with a dimmer. My soldering skills are fairly out of date but I managed all the same.

It was a neat class and I look forward to using some of that knowledge on the builds I'm helping with (as well as my own).

The glider's 3rd battery now has a sewn carrying handle that makes it easier and safer to install in the crowded battery box.

Next, I need to devise a retaining system for it and finish the wiring harness that connects it to the rest of the system.

Progress will slow for the next day or two because the things I have ordered (epoxy, lead shot, etc.) will be delayed while we ride out a snowstorm that should end tomorrow.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Safety #Battery #Sewing

Where does the 'typical' glider battery go in this electric glider?

In the battery box, next to the high voltage motor batteries.

My final decision on this battery location depended on the weight and balance measurements I made last week. It shows that I need to add weight to the tail...so, the heaviest batteries are full-aft in the battery box, and this 3rd battery goes in front. All of this is aft of the tail in the fuselage/tail boom.

I now need to sew some sort of sack and carrying handle for this battery. It's not a heavy battery, but I want a secure way to handle it as I install/remove it.

Above my hand is a black/gray marbled-pattern object. It's a yoga block. That semi-dense foam will be cut to size to take up any dead space along the sides of the battery box to prevent the batteries from banging side-to-side if the other retaining systems fail.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Safety #Battery

My glider will use a tow rope that is too strong. That rope, when under maximum pull, may damage the glider.

I need to install a weak link as a mechanical 'safety fuse'.

Here is one weak link system I can use:

https://wingsandwheels.com/tost-weak-link.html

But which weak link is appropriate for my glider?

Federal Aviation regulations require a tow rope (or weak link) to have a certain breaking strength with regard to the maximum operating weight of the glider:

"The towline used has breaking strength not less than 80 percent of the maximum certificated operating weight of the glider or unpowered ultralight vehicle and not more than twice this operating weight."

https://www.ecfr.gov/current/title-14/chapter-I/subchapter-F/part-91/subpart-D/section-91.309

To complicate matters, my glider can carry 400 pounds of water ballast. When I'm flying 'dry', I would prefer to have a weak link that is just strong enough for the dry glider, and when flying 'wet' I would prefer a (somewhat stronger) weak link appropriate to the heavier operating weight.

See the second graphic, which shows which Tost weak links I can use in the dry or wet ballast condition.

I will start out getting the weakest weak links allowed (green, yellow, and white) and see if that launches me well without premature weak link breaks.

Pro-tip. Try not to lift the rear end of the ground launch car.

https://youtu.be/kd9QxRPb3hk?t=33

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Math #Weight #Safety

My glider needs the center of gravity shifted aft, so I need to add weight in the tail.

The first photo is looking into the rudder cove (rudder removed). I can bolt some lead plates to the flat face of the vertical fin spar, but I will need even more weight added back here.

Note that the rudder hinge support is glowing green...a flashlight on the other side is illuminating it.

That part is hollow and it's nothing but dead space. I can add lead shot and epoxy in there.

The second photo shows the view of this pale green fiberglass part from the other side. Before I can add lead shot in there, I need to add a dam to retain it while the epoxy cures.

Third photo shows a piece of scrap Plexiglas that fits up against the end of the rudder hinge support.

Final photo shows the Plexiglas dam glued into place with RTV silicone caulk. It has a semicircular cutout that allows a larger diameter piece of tubing to be placed there while I pour lead shot and epoxy into a funnel and fill that empty space.

Half of the caulking work was done blind and by feel. I am accessing this tight space from the inspection port in the side of the vertical fin. There is just enough room for one hand and this part to pass through the port and then get positioned. I practiced before applying the caulk so I knew exactly how to position and twist the part so that I didn't make a mess and most of the caulk ended up in the desired location.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Epoxy #Ballast #Lead #Plexiglas

Like most GA aircraft, my plane has a very loud interior. Whenever I fly, my watch fairly constantly warns me about excessive noise levels. Usually 95 db, occasionally I see 100 db. Noise cancelling headsets are basically required to be in the aircraft while the engine's running. But even then, the noise is still noticeable.

Searching on the vansairforce forums (<3 old school forums), it seems that a lot of the cause of excessive cabin noise is basically panels vibrating against each other, and adding soundproofing material (tape, foam, etc.) helps to massively reduce the noise. The problem then becomes an optimization problem of where to apply the soundproofing to maximize effect while minimizing weight.

I'm thinking of taping a bunch of cheap mics to various spots in the airplane, recording the sound amplitude to try to figure this out. I'm hoping to be able to achieve a noticeable decrease in sound levels doing this.

Of course, I'll also decrease sound levels by just adding carpet to various panels, which I want to do anyway (my cabin is spartan). But I also want to see what the combined improvement will be.

The electric glider's two main batteries each weigh about 16 Kg (36 lbs). I need a positive restraint system that can handle vibration and especially negative G.

Yesterday evening I epoxied in place some retaining blocks for the two battery clamping bars, but the garage gets cold overnight. I placed an incandescent lamp over the top of the battery box and wrapped some towels as a 'tent' to keep the warm air from easily escaping. This allowed the battery box to stay slightly warmer and accelerate the curing of the epoxy.

The second photo shows one end of a battery clamping bar (yellow) that fits under a carbon fiber inverted shelf (black). On each side of the clamping bar there are now two blocks of garolite (pale green) that prevent the battery block from sliding off to the side.

Garolite (G-10) is commonly used as the substrate for printed circuit boards, and you can get it in significant thickness, which is what I need.

https://en.wikipedia.org/wiki/G-10_(material)

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Epoxy #Chemistry #Temperature #Garolite

For the glider's ground support equipment, there is good news and bad news in the first photo.

The good news is that the eScooter has more than enough pulling power to move the glider about on a smooth, level paved surface.

The bad news is that this version of the red tow bar means that any sideways push against the tail of the glider is transmitted to the eScooter...and makes it extremely difficult to keep the scooter from toppling over.

I had to re-design the tow bar.

The second photo shows what I've come up with. Now the wheel on the yellow tail dolly carries the weight of the glider's tail and reacts to any sideways loads. The eScooter merely needs to provide the pulling force and doesn't have to deal with those sideways forces. That should be much easier and safer for the driver.

The next time I assemble the glider at the airport, I'll give this towbar a final test with the eScooter.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Logistics #Design #Dynamics #Physics

My friend @cyanoacry (much more active on bluesky, @cyanoacry.bluesky.social) has a blog about the kinds of thing he gets up to with his Rutan Defiant. Yesterday, he posted a highlights of 2025, which included 2 live streams while flying! Plenty of people record and publish their flights after the fact, not that many livestream them!

https://cyanoacry.substack.com/p/defiant-hijinks-dec-2025-part-2

Where is the center of gravity of the empty glider located?

If you measure the location of the main wheel and tail wheel (reference to something such as the glider's nose), and the weight each of them carry...you can do the math to answer that question.

Where is the center of gravity when the pilot is in the glider?

Climb in, and then take the same measurements.

Now I know if I need to add trim weights to the nose or tail, and how much.

Determining center of gravity location is critical for safety of flight and good handling characteristics. I'll do these measurements and math more than once so I can be very confident of the results.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Aerodynamics #Math #Mass #Weight #Balance #Safety

My EAA chapter has acquired a second airplane build. We're starting up a Youth Build project and trying to engage the local schools.

#kitplane #experimentalAviation #avgeek #aviation #flying #homebuilt

One surface of one glider wing has now been covered with mylar gap seal tape.

Tomorrow I will flip the wing over and apply gap seal tape to the other surface.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Fairing #Drag #Aerodynamics

Gliders often go to significant lengths to reduce drag.

My flaperons are driven by a push-pull tube that exits the wing skin and pushes against an external drive horn. There are two of these setups on each wing...four external devices that need fairings.

But they and the flaperons move. That complicates things.

First photo shows one push-pull tube and drive horn without fairings.

Second photo shows the inner/smaller fairing that will eventually be glued into place.

Third photo shows both fairings in place and the flaperon near the limit of its down travel.

Fourth photo shows both fairings and the flaperon approaching the limit of its upward travel.

One fairing of the two pairs on one wing are drying overnight. Tomorrow morning, I will make final adjustments to the remaining inner fairings and then glue them in place.

I'm using RTV silicone, which needs humid air to cure well. It's winter in New Mexico and the air is super dry. I have put a very large pot of water on the wood stove to humidify the air overnight.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Fairing #Drag #Aerodynamics

I need to make a cloth canopy cover for the glider.

Now that I have the canopy installed, I can measure overall length of the planned cover and the width at various points.

I'll lay out a pattern on paper that is 1/4 or 1/3 of the overall width...like gores for a hot air balloon.

I have three different types of stretch fabric from very light to somewhat heavy. We'll see what results I get.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Sewing #Fabric

I just finished the first draft of a Youth Airplane Build charter for my EAA Chapter. I've never made one before but now I have a nice 5 page document specifying how the program will run. It needs some work, input from others, board approval, blah blah blah.

As a kid I never appreciated the amount of coordination and work things like this are, ignoring the complexity of building the aircraft itself. It should be a fun and rewarding experience once we get there.

The glider winglets need a protective box during transport to and from the airport.

Now that I know it's big enough to hold them (I'll add foam cushions later), it's time to slap on some leftover red and yellow Rustoleum on the exterior.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA

The FAA registration number has been applied to both sides of the fuselage tail boom.

Tomorrow I will apply mylar gap seal tape along the junction of the moveable rudder and the vertical fin.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #FAA